Service overview and feature Service overview and feature

|

|

We are pleased to offer customers the ability to produce a variety of 3D physical models using the outputs from UC-win/Road, UC-win/FRAME(3D), UC-1 Series and Allplan on a special 3D printer. |

|

Related

Information Related

Information  |

3D Physical modeling Service movie (July 13, 2010) 3D Physical modeling Service movie (July 13, 2010)

- 3D Physical modeling service: model making

New product information New product information

|

|

|

For this service, we use a Zprinter 650, the highest spec model from Z Corporation. Zprinter 650 can create full color 3D models using inkjet printing method. It can produce physical models with a maximum size of 254mm (w) x 381mm (h) x 203mm (d), the largest in the industry.

Larger models can also be produced by dividing up the digital model into smaller sections and then merging them to reproduce entirety of the final physical model.

The Zprinter 650 can read STL, VRML, PLY, 3DS, ZPR file formats. Other file formats can be utilized by using other 3D modeling tools, such as 3ds Max, therefore, 3D models can be generated in virtually any 3D model formats to be modeled.

|

Zprinter (Tokyo HQ's showroom) Zprinter (Tokyo HQ's showroom) |

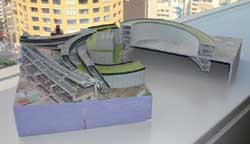

The image below shows a physical model produced by Zprinter 650, using a highway junction model data from UC-win/Road; the piers were produced based on the results from UC-win/FRAME(3D), a non-linear linear analysis program.

From the physical model in the below image, the junction's entwined loop roads and the details of the steel tower and the ventilation facilities can be seen.

|

Ohashi JCT cross section model Ohashi JCT cross section model |

UC-win/FRAME (3D) can output the deformation data in standard 3ds format.

The physical model shown was produced by the Zprinter 650 using the 3ds

data. Deformed condition is reproduced as a physical model.

UC-1 and Allplan are both capable of exporting models in 3ds, therefore, 3D physical models can be produced using these software programs.

Using the 3ds Max Plug-in, "POV-ray to Max", which was jointly developed with Associate Professor Kobayashi of Arizona State University, UC-win/Road data and terrain data can be exported to 3ds Max; choose the region to be reproduced and adjust the model data including the cuttings.

Then users can export the data in OBJ file format which is used in many CG software programs and import the data into "Magic", a special program for creating 3D physical models. Magic will correct modeling errors, configure the data for modeling and finally produce the physical model using the Zprinter.

Time that the Zprinter 650 takes to produce models varies on the size of the model (from less than an hour up to ten or more hours), but compared with the time and effort that is taken for the production of architectural models and large-scale city models, Zprinter 650 can produce models in short time period as long as all the necessary data is available.

It is needless to say that 3D models can be used for various purposes including design examinations, detailed verifications and exhibitions. |

|

3D Modeling sample quotation (Before-tax price) 3D Modeling sample quotation (Before-tax price)

|

|

| 1: Taishi Junction Model |

Size of the physical model created:

D25(cm)×W23(cm)×H2(cm) |

Total Man-hour

(Sub-total A) |

2.6(h) |

Man-hour

(Sub-total B) |

28,480yen |

Direct labor costs

(Sub-total C=A*B) |

74,048yen |

Administration cost

(Sub-total D) |

37,024yen |

| Material cost, indirect cost (Sub-total E) |

37,950yen |

| Total(C+D+E) |

149,022yen |

|

|

| 2: Ohashi Junction Model (north part) |

Size of the physical model created:

D23(cm)×W30(cm)×H13(cm) |

Total Man-hour

(Sub-total A) |

2.6(h) |

Man-hour

(Sub-total B) |

28,480yen |

Direct labor costs

(Sub-total C=A*B) |

74,048yen |

Administration cost

(Sub-total D) |

37,024yen |

| Material cost, indirect cost (Sub-total E) |

296,010yen |

| Total(C+D+E) |

407,082yen |

|

Taishi Junction and Ohashi junction madels are award winning works made

by Metropolitan Expressway Co., Ltd.at 3D VR Simulation Contest

|

|

|

|