| Enable Smooth Communication with Manufactures by using 3D images for Product Design , Product Catalogues, to the point of purchase advertisements. |

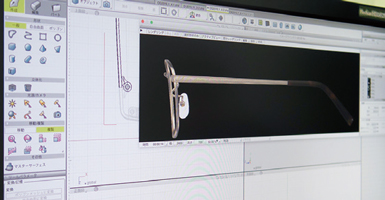

Mikio Konaga, who is the planning office manager and designer at ONAGA MEGANE Co., Ltd. headquartered in Fukui City, Fukui Prefecture, uses Shade3D equipped with his own script. Other designers also work with the same Shade3D software.

"We are a wholesaler of eyeglasses. We ask manufacturers to make products designed by our in-house designers and sell them to retail stores nationwide. Since all the design is created in-house, we design glasses with Shade3D and use it for catalogs and POP advertisements."

While many companies use photographs in product catalogs, Onaga Glasses use only images created with Shade3D. So when the product is ready, they have a catalog ready. The advantage of using Shade3d images is that the sales staff don't need to spend time to take pictures for POP advertisements when they are in a hurry.

"The promotion video posted on the homepage also uses the animation function of Shade3D, so anyway, I use Shade3D for everything." The advantage of using Shade3D when designing is that it can significantly reduce the time from design to manufacturing. Other companies generally use Illustrator or CAD software for eyeglasses to design, prepare prototype samples and color samples before mass production, and then manufacture them. Onaga glasses try not to make prototype samples as much as possible.

"Since CG software is 3D, you can't fake. Therefore, the design will be accurate. Based on that design, we will make fine adjustments with the manufacturer, and the manufacturer will immediately understand it when it's 3D. Since the product image can be shared with each other, there is no need to make a prototype."

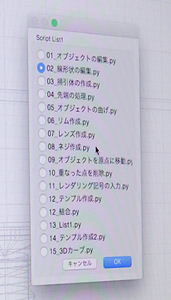

Also, another attraction is that it is easy to express the soft lines of glasses with Shade3D. They assesses that it can draw as efficiently as vector image editing software and can be used commercialy."The finish may be faster than other software when considering correction and making color variations." Their self-made script has a function that allows them to enter numerical values and draws the rim of the glasses while controlling them numerically, aligns points, and moves to a specified location.

They made a script that can automatically shape glasses while resembling the operation of Illustrator. There is also a script that selects multiple corners and rounds them at once to round the corners.

He showed us the glasses made by 3D printing. The screwed part of this glasses is made with a 3D printer. He says that the 3D printing assist function used at this time is very convenient.

"This part usually takes about a month to manufacture, but in the case of 3D printing it's completed in a week. In other words, it is finished in a small lot with a short delivery time, and there is no inventory risk. Isn't it efficient?"

He also gave an advice for those who have a plan to use Shade3D. "If you deepen your understanding of control points and line shapes, you can make anything. You can learn the tools and detailed functions later. Also, if you can manipulate the lines of the vector, you will be able to learn more quickly."

|

|

|

| Model of glasses and a setscrew actually used for output |

Script List |

|