About the construction type and structure

They are in accordance with "(3)Specification and civil engineering and construction management standards" of "Common specifications for civil works/ Administration standards for construction etc." established by the Ministry of Land, Infrastructure, Transport, and Tourism of Japan. However they are to be restricted to the earthwork (embankment and earth cut) and road earthwork etc.

About design section

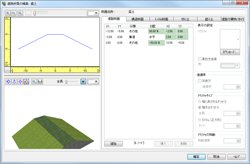

As for the filling shape and cutting ground shape (including the linear),

input them by using "Road edit" function which is a function

embedded in UC-win/Road itself (Figure 2). It is also possible to import

the design data much easily by using LandXML.

|

|

|

| Figure 2 Edit of road section |

|

3D laser scanning

modeling service |

|

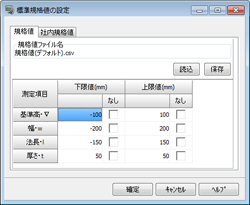

Standards for work progress control

When limiting to the above-mentioned construction type and structure, measurement

item has only height, width (length of slope) and thickness. The standard

value can be specified according to the object structure and other standard

value such as the internal standard value unique to a specific company

can also be defined (Figure 3).

|

|

|

| Measurement item |

Standard value |

| Standard height ▽ |

-50 |

| Length of slope l |

l<5m |

-100 |

| l≧5m |

Length of slope -2% |

| Width w1,w2 |

-100 |

|

|

| Figure 3 Setting of standard value |

|

|

About the road section

The point cloud data which can be obtained by using 3D laser scanning service

of our company etc. and ground level TIN data are applied to the road section.

By recognizing the road section (Figure 4), it is possible to obtain a

great deal of measuremed data at every specified measurement point in a

short time.

|

|

Figure 4 Comfirming and editing

the road section |

|