New Development through INFRONEER Holdings

Maeda Corporation was founded in Fukui Prefecture in 1919 (established as the current company name in 1946). Through more than 100 years since then, Maeda has expanded its business fields from mountain civil engineering to urban civil engineering, architecture, and overseas. Today, Maeda consists of three divisions other than corporate administration: Management Innovation Division, Building Division, and Civil Engineering Division. Under the Head Office (Chiyoda-ku, Tokyo), Maeda has 12 branches in Hokkaido, Tohoku, Kanto, Tokyo Building works, Tokyo Civil Engineering Works, Hokuriku, Chubu, Kansai, Chugoku, Shikoku, Kyushu, and Okinawa. over 3,200 employees work in these 12 branches.

This time we interviewed ICT Promotion Group, which belongs to Civil Engineering Technology Department within Civil Engineering Division that oversees all aspects of the civil engineering field. The Dept. is responsible for 1) technology development, 2) dissemination and spreading of technology, and 3) technical on-site support. In particular, ICT Promotion Group is responsible for on-site support through all aspects of ICT, such as technical support, environmental improvement, human resource development, technological development, and BIM/CIM support.

In October 2021, Maeda established a joint holding company, INFRONEER Holdings Inc., with Maeda Road Construction Co., Ltd. and Maeda SEISAKUSHO CO., LTD. The company brought together the technological expertise and partnerships cultivated by respective companies to address infrastructure issues. The company declares that it will develop as "a comprehensive infrastructure service company" that provides optimal services worldwide with innovative ideas, free from preconceived notions. Reflecting this, the ICT Promotion Group has is also considering the needs for ICT utilization that extend beyond conventional business domains, according to Mr. Kudou, Senior Manager of Group.

|

|

|

Mr. Shinichi Kudou,

Senior Manager of Group, ICT Promotion Group,

Civil Engineering Technology Dept.,

Civil Engineering Division |

Mr. Yuta Sakafuji,

Assistant Section Chief,

ICT Promotion Group,

Civil Engineering Technology Dept.,

Civil Engineering Division |

Mr. Nozomu Muroya,

Chief of ICT Promotion Group,

Civil Engineering Technology Dept.,

Civil Engineering Division |

Effective Application of UC-win/Road to Traffic Restrictions and Earth and sand Transport Operations

The company's involvement with UC-win/Road dates back to 2006, when Design Engineering Dept. at that time introduced it.

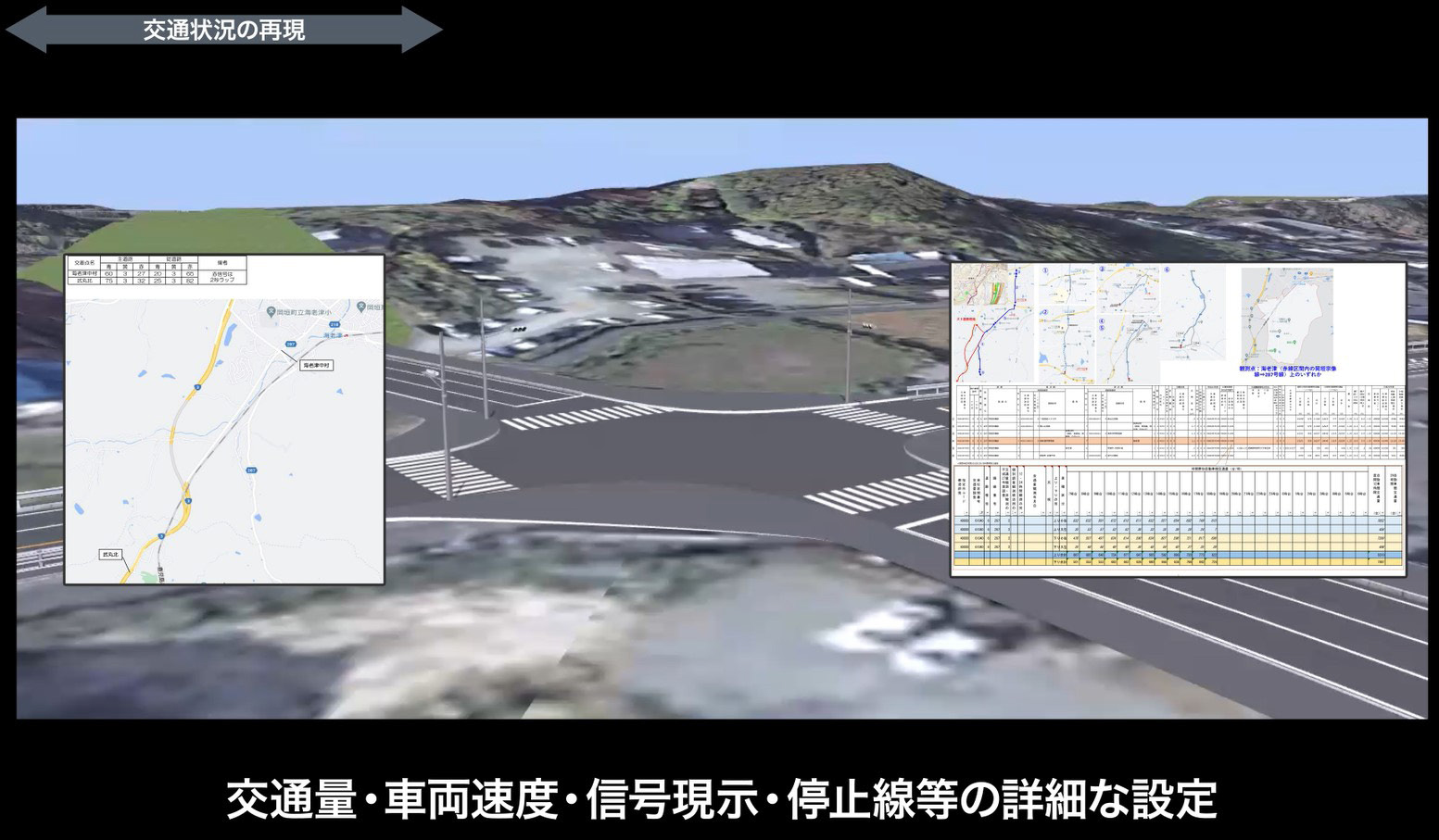

Meanwhile, ICT Promotion Group introduced here first applied UC-win/Road to actual work in 2018. The company participated in a road improvement project that required traffic restrictions for occupying the road for construction. In such a case, until then, it was usual to prepare paper documents including drawings and photographs, notify the police, or consult and coordinate with the client and the departments concerned with the project. In this project, on the contrary, it was proposed to use 3DVR to simulate various situations such as the lane reduction due to traffic restrictions and the resulting congestion, as well as traffic stagnation at red lights. It was intended to facilitate consultation smoothly and build consensus easily by making the work site more visible to drivers and pedestrians. The simulation is used in addition to conventional materials.

As both the client and the contractor realized its effectiveness when making consultation by using it actually, its use was spread to various other sites. Later, UC-win/Road was utilized for two plans of earth and sand transport of tunnel construction and one restoration work in Tohoku, all of which the Group was involved with directly. In addition to them, there must be other cases where the sites have adopted UC-win/Road on their own, says Mr. Kudou, Senior Manager of Group.

Among them, the earth and sand transport plan for tunnel construction was simulated using UC-win/Road in 2021, reflecting the conditions of the actual route to be taken. It is used to determine the optimal number of dump trucks to transport construction generated soil and so on.

|

|

|

|

| UC-win/Road is used for simulation of traffic restriction and earth and sand transport operations etc. |

Through the use of UC-win/Road so far, he has evaluated it as "a good software. However, sometimes they have to start from explaining UC-win/Road to those involved in the site and the owner, and he believes that this will be more beneficial if it is widely recognized, and literacy is increased on both sides.

"If UC-win/Road is recognized to some extent and its fundamentals are understood by the people involved in the project, I think it will be utilized in a wider range of situations."

Expanding Use of UC-1 Series and ES in Design in a Wide Range of Fields

Mr. Yuta Sakafuji, Assistant Section Chief of ICT Promotion Group says that as a general contractor that handles a large number of public works projects based on a design-bid-build order system, design work that the civil engineering depts. of Maeda deals with are mainly divided into the following two ways: 1) cases where the original design conditions have changed and the work must be redesigned on the conditions that match the actual site (the conditions tend to be complex), and 2) cases of the design-build process where design and construction are ordered together (mostly for private companies). After working in the Civil Engineering Design Dept, Mr. Sakafuji was transferred to Information Platform Division, (Research Center for Infrastructure Management) of National Institute for Land and Infrastructure Management (NILIM) from 2019 to 2020 fiscal year to work for developing standards for BIM/CIM. With such experiences, he is currently responsible for supporting the work sites and technological development centering on BIM/CIM in the Group.

The design sections of Maeda have been using the design software products of UC-1 Series for many years, although some of them have changed their names. He recalls that when he joined the company 15 years ago, the software products he came into contact with first were the arbitrary plane frame analysis program "FRAME (in-plane)" and the reinforced concrete (RC) section calculation program "RC section calculation" (both are from "UC-1 series").

The company's design sections are divided into four major fields: 1) ground, 2) bridges and structures, 3) aseismic structures, and 4) tunnels, with each field basically using the above two kinds of software. Furthermore, they have been using many titles of "UC-1 Series" software continuously: for example, “Retaining wall design” and "Temporary piled jetty design" for ground, and "Abutment (design)" for bridges and structures.

He mentions a private project in which he analyzed a water tank of RC structure in 2014 as "probably the first case in which we used Engineer's Studio® (ES). At the time, while 2D design was the basic method used and FRAME (in-plane) was mainly used, the project required three-dimensional analysis such as loading conditions and structural analysis. It was assumed that two-dimensional analysis with the existing tool would cause very large specifications. That's why they introduced ES.

Maeda currently makes full use of various software products of UC-1 Series as before. On the other hand, as the use of 3D analysis has increased significantly, utilization of ES has also expanded in all four of the aforementioned fields. As the background of this, he appreciates the real-time and visually easy-to-understand results of calculations and analysis provided by these software products. He also mentions the addition of functions to the UC-1 series, such as the function of 3D model rendering that supports BIM/CIM, as well as the flexible addition of functions through add-ons to "WCOMD", a 2D non-linear dynamic/static analysis program for RC structures, which meet the Company's unique needs.

|

| Engineer's Studio ® is utilized for designing diverse structures including bridges |

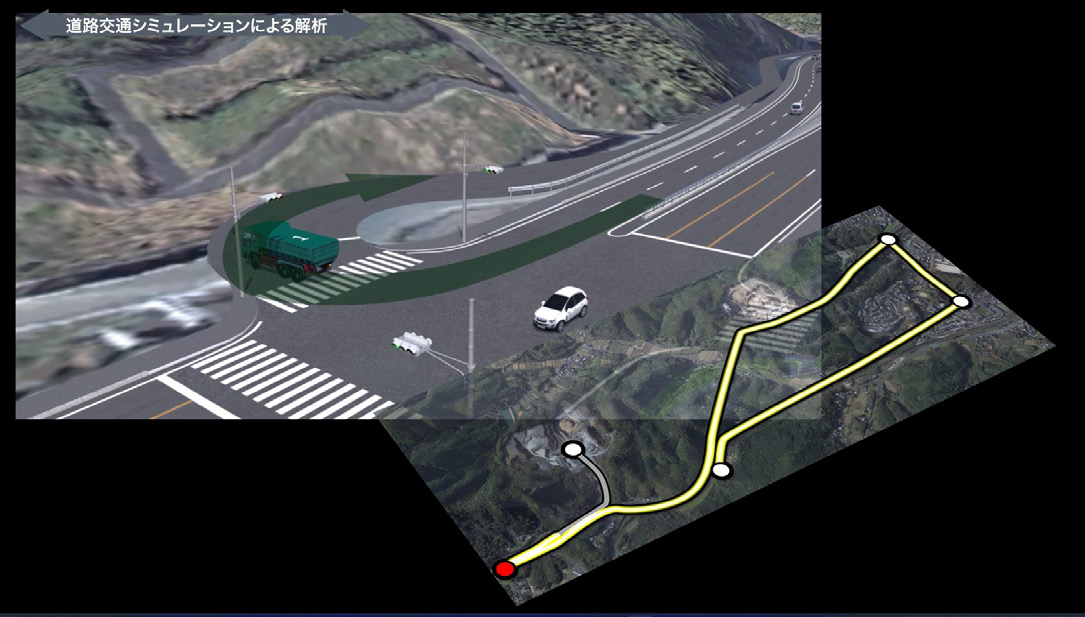

Selection of Tools According to Design Conditions and Evaluation of Results

The group is engaged in supporting the deployment of BIM/CIM and existing ICT tools in work sites. As part of this effort, Mr. Nozomu Muroya, Chief, who is mainly responsible for the use of UC-win/Road within the group, presented their own approach to traffic simulation. Rather than simply relying on the data obtained through simulation, he also conducted a follow-up survey using dump trucks on site. He explains it is significant that by carefully examining the consistency between the survey results and the simulation, the reliability of the simulation data itself is increased, making it more useful.

Moreover, in the design sections of Maeda, the number of ES users has been steadily increasing as a result of the shift of the software products they use from FRAME (in-plane) to Engineer's Studio® (ES). Mr. Sakafuji points out that although the shift in analysis from 2D to 3D has made it easier to visually understand loads and so on, it has also made it easier for engineers to make mistakes due to increasingly complex constraint conditions, etc. He believes that ES should be treated carefully as FEM analysis software, not as design software with which results are generated by entering conditions.

"We think the tools we are using are very good respectively, but design conditions vary from one case to the other. Therefore, it is important for users to think carefully about how to use the tools according to respective conditions." The key point there is not simply to "try it out," but to make sure that the software is really being used in a way that suits the respective conditions, according to Mr. Kudo, Senior Manager of Group.

Mr. Sakafuji, on the other hand, developed his talk to recent advances in software, which can provide answers immediately upon entering conditions and quantity calculation etc. However, he is concerned that while productivity improves with the enhancement of software functions, the technical skills cultivated in a time-consuming manner may be reduced. He also stated that some efforts will be necessary to continually improving technical capabilities.

In this connection, Mr. Kudo, Senior Manager of Group noted that it is possible to sense if there is a calculation error in the answer derived from manual calculation to a certain extent, but that it is difficult to recognize if the output is wrong unless one understands the detailed mathematical formula for the answer automatically generated. In such cases, although the interface is becoming more and more difficult to make mistakes at the input stage, it is still important to develop a "sense of understanding the output when you see it."

|

| ICT Promotion Group promotes advanced utilization of existing ICT tools and effective on-site deployment. |

|