About influence on company since the Great East Japan Earthquake disaster,

Mr. Fukuo Sakurai, Chief Executive Officer of Techno Tohoku Corporation

says that the principal earthquake on March 11 was certainly serious, but

the damage of the aftershock of April 7 was rather bigger.

The Tohoku ? Pacific Ocean Earthquake (magnitude 9.0) that occurred at

about 2:46 on the afternoon of March 11 with Sanriku offing as its seismic

center brought quake registering a weak-6 around Izumi-ku, Sendai city

where the headquarters office of Techno Tohoku is located. Though there

were intermittent after quakes afterwards, wariness to after quakes was

gradually moderating towards the beginning of the next month.

However, having a seismic center off the coast of Miyagi prefecture, an

M. 7.1 aftershock occurred at about 11:32 pm on April 7, nearly a month

after the main shock. Earthquake intensity of a strong 5 was observed around

Izumi-ku.

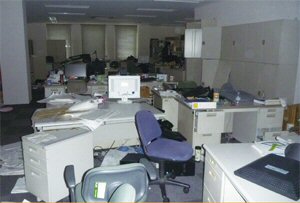

As a result, Whereas PC monitors and some lockers fell down during the

main shock, almost all lockers, bookshelves, and partitions fell down during

the aftershock not to mention monitors, with materials being scattered

on the floor.

The second user company we introduce this time is Techno Tohoku Corporation,

a civil engineering consultant that covers various fields. Techno Tohoku

has been using FORUM8 products mainly as civil engineering software till

now. In addition, Techno Tohoku played an important role in developing

"Bridge inspection support system" of which FORUM8 released the

first edition in January 2008, by technological cooperation. Therefore,

we focus on Bridge Maintenance Group, First Engineering Department and

Bridge Substructure Group, Second Engineering Department.

|

|

|

(from left) Mr. Kiyohiko Sato (Bridge Substructure Group, Second Engineering

Department); (from left) Mr. Kiyohiko Sato (Bridge Substructure Group, Second Engineering

Department);

Mr. Fukuo Sakurai, Chief Executive Officer;

Mr. Naoki Matsunaga, Mr. Kyuichi Fujita (Bridge Maintenance Group, First

Engineering Department) |

| Covering Highways, Transportation, and Various Types of Structures Including

Bridges |

"We don't have so many projects that are dealt only by our company.

Rather, we have more subcontract works (to support the contractor)".

Techno Tohoku is founded in 1989. Starting mainly with design of structures

including highways and bridges, it has gradually expanded the fields and

services.

Currently, it is based in the headquarters office (Izumichuo, Izumi-ku,

Sendai city) and Koriyama office (Omachi, Koriyama city, Fukushima), having

about 50 employees. Its services are as follows.

(1) Highway / a transport technology such as preliminary / detailed design

of highways, transportation planning, traffic simulation, and data analysis

(2) Structural technology such as design of bridge superstructure / substructure,

bridge inspection, design of the electric wire underground multi-purpose

duct, and sewerage design

(3) Environmental technology for investigating natural environment and

living environment

(4) Hydraulic engineering for designing river and coastal structures

(5) Disaster prevention technology for planning and designing countermeasures

for rock fall and slope failure.

Mr. Fukuo Sakurai says Techno Tohoku has a wide range of services for a

subcontractor.

Bridge Maintenance Group, First Engineering Department conducts field survey,

tests, and repairing design for various structures including bridges.

Public works expenditures are reduced while a large quantity of the social

capital stock provided during the high economic growth period reach update

time. Along with this, in recent years, asset management has attracted

attention. This means performing maintenance with the highest cost-effectiveness

by regarding social capital as asset widely and grasping its damage or

deterioration over its life cycle. In addition, toward extension of life

of the social capital, the significance of knowledge about various maintenance

and repair / reinforcement technology is also getting greater. In this

context, the business records of bridge inspection for Ministry of Land,

Infrastructure and Transport and local government that Techno Tohoku undertakes

amounts to around 300 bridges a year.

Bridge Substructure Group, Second Engineering Department is in charge of

design work of bridge substructure that is the mainstream of Techno Tohoku

since its foundation and other general structures, boasting abundant experiences.

Not to mention six prefectures of Tohoku, it responds to projects in Kanto,

Kansai, and Hokkaido. Other than design of new structures, it puts emphasis

on seismic reinforcement design as well as dynamic analysis.

One of the unique attempts of Techno Tohoku is Civil Design Group established

in the Second Engineering Department. Staff members of a short-term contract,

who had been assigned to each department, were reorganized as an independent

function. By gathering auxiliary works such as drawing or quantity calculation

that extends to multiple sections into the group to have them performed

in sharing them, efficiency of the organization as well as leveling the

works are designated.

|

|

|

Inside the office right after the earthquake disaster (left), Inside the office right after the earthquake disaster (left),

and inside the office on business activities shot from the same direction

(right) |

| Commutation and Lifeline Temporarily Hindered |

In this earthquake disaster, not only the earthquake itself but also massive

tsunamis generated by this brought about damage compositely, which is assumed

the greatest in the history of disasters in the end. In Miyagi in particular,

the casualty figure exceeds 60% of the whole disaster area, indicating

how serious the damage is.

In Techno Tohoku Corporation, though there was no human damage to the employees

and their families, some had their parents' houses washed away by the tsunami.

In addition, destruction of buildings or depressions of highways were frequently

seen around the headquarters office. Moreover, an overpass was damaged

between Izumichuo Station, that is the nearest station to Techno Tohoku

on Sendai-city subway Namboku Line and the adjacent Yaotome station. Its

restoration took until April 29 when operation was reopened on the whole

line.

In the headquarters office, as mentioned above, all PC monitors dropped

from the desk in the main shock on March 11. For some time after that,

office staff laid the monitors on the desktop when leaving the company

to prevent dropping. In April, when they returned to the usual pattern,

aftershock occurred on April 7. All monitor dropped again.

In addition, as to bookshelves etc., a tip-over safety measure had been

taken by fixing them with anchor bolts to the board; consequently, it was

only that some lockers fell down during the main shock. In contrast, anchor

bolt fell out of the board during the aftershock, resulting into greater

damage than the main shock.

But the seismic countermeasure for the server was strengthened when headquarters

office was transferred to the current place from a different building in

Izumi-ku in January 2010. That made it possible not to cause a significant

hang-up in business though plural monitor were broken, says Mr. Fukuo Sakurai.

He continues, "The server might have been broken if it was as used

to be, causing more serious trouble".

Furthermore, since the Company had prepared for the final effort for the

delivery of goods in the end of the fiscal year, it had not a small influence

that the commuting means were interrupted and commodity supply of such

as electricity, water and paper was cut off though temporarily.

Flow Towards Joint Development of "Bridge Inspection Support System"

Evaluation of Software and New Possibility |

The number of routine inspection of bridges undertaken by Techno Tohoku

within the district of Tohoku Regional Development Bureau, Ministry of

Land, Infrastructure and Transport (MLIT) is increasing year by year. After

2006 in particular, it reaches around 300 bridges a year. On the other

hand, those works include not only enormous and simple iterative processes

but also organizing photos and creating a large number of drawings. In

fact, in the end of the fiscal year when these works concentrate, they

got through the works by working overnight or recruitment of extra staff

of short-term employment.

Mr. Kiyohiko Sato, Deputy Manager of Bridge Substructure Group, Second

Engineering Department recalls that they sought for the way of simplifying

these works to improve efficiency. For example, it was required to develop

software to support not to produce an input error when entering information

such as extent of damages or parts based on the created drawing into the

server of MLIT.

It was when MLIT provided "Bridge routine inspection procedures"

(scheme) (March, 2004) that Techno Tohoku proposed joint development of

a program that reflects the scheme to FORUM8. They started working on actual

development around 2006. It took about a year to complete the program,

to which small adjustments were made during another year. It was made into

a product (first edition release) as "UC-1 Bridge inspection support

system" in January 2008.

This records the damage situation based on the close visual inspection

in bridge routine inspection, prepares inspection records, and create member

and damage drawings in conformity with the bridge routine inspection procedure

(scheme). Based on this, FORUM8 also released the 1st version of "UC-1

bridge inspection support system" (National Institute for Land and

Infrastructure Management version) that conforms to "Basic data collection

procedure (scheme) about the highway bridge" (MLIT / National Institute

for Land and Infrastructure Management) in April 2010.

According to the test calculation in the company, the cost required for

the development can be recovered in approximately two years owing to the

effect of introducing the software. Mr. Kyuichi Fujita, Councilor of Bridge

Maintenance Group, First Engineering Department states his opinion that

it leads to advantages beyond expectation. For example, although an expert

finally perform a check, errors decrease, and the staff member of the above-mentioned

Civil Design Group can handle most of the works within a short time.

Mr. Naoki Matsunaga, Manager of the Group considers that the software has

received a certain evaluation up to the level of maintenance design. He

also mentioned future possibilities including application to inspection

of not only bridges but also highways and their incidental facilities and

other structures, or functional expansion such as visualization of damages

and calculation of repair costs.

In addition, Mr. Kiyohiko Sato expects that a tablet PC can be used on

site if the software comes to support cloud-type service, and that it will

lead to easy and speedy work.

Further, in consideration of concern about shortage of skilled engineers

accompanied by rapid aging and birthrate declining in Japan, Mr. Fukuo

Sakurai explains a function of presenting a repairing method of cause-measure

type and improvement of the inspection technology through this, and possibility

of proposing a construction method that links with the cost of repairing

presented.

|

|

|

|

|

Bridge inspection support system (left) released by FORUM8 through the

technical cooperation of the Techno Tohoku. Bridge inspection support system (left) released by FORUM8 through the

technical cooperation of the Techno Tohoku.

(Right) National Institute for Land and Infrastructure Management version

on the basis of this |

Urgent Inspection in the Disaster Area

Reveals Actual Feeling and Knowledge |

Following Great East Japan Earthquake, MLIT, the Metropolitan district,

and at least the prefectures in the disaster area conducted an urgent inspection

of risk areas of earth-flow disaster. Techno Tohoku also investigated various

fields such as bridges, highways, harbors, rivers, sewerage etc. in three

prefectures of Fukushima, Miyagi, and Iwate.

In conjunction with this, Mr. Kyuichi Fujita, who has been coping with

research mainly on the bridge, realized again that the know-how of the

bridge inspection technology accumulated so far is very useful. He again

persuades necessity of organizing a system in which knowledge obtained

through research can be reflected in the repair design.

Similarly, Mr. Naoki Matsunaga mentioned the difference between the state

of disaster seen through news and the actual feeling acquired on the spot,

based on his own experience of conducting field investigation. He then

draws an approach to aim at towards restoration. That is, to act on the

standpoint of improving the situation around oneself as an individual,

while thinking on a large standpoint of such as town planning and urban

planning as a civil engineering consultant.

"What I felt at the site of disaster (for research after disaster)

is that some cases are seen where the way of collapsing is different from

what had been expected traditionally in this disaster."

For example, the way of breaking that could not be explained in the conventional

method of thinking was seen in the bridge substructure, as Mr. Fukuo Sakurai

says, remarking that it may have some influence on design methods in the

future.

(Interviewed and written by Takashi Ikeno)

|

Staff of Techno Tohoku Corporation Staff of Techno Tohoku Corporation

(Mr. Fukuo Sakurai, CEO, at the center in the front row) |

|