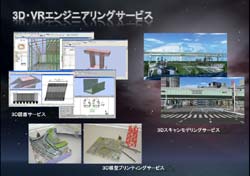

- FORUM 8 offers the tripartite g3D VR Engineering Serviceh, which consists of "3D Laser Scanning and Modeling Service", "3D Physical Modeling Service and "3D Drawing Serviceh.

Each service is described on this page:

1. 3D Laser Scanning and Modeling Service

- In the surveying and construction industries, there is a growing interest in 3D modeling using point-cloud data, which is collected using high-precision mobile GPS device. In UC-win/Road Ver.5, there is a new function that enables users to import and edit point cloud data in real time. (UC-win/Road Point Coud Modeling) There is a variety of uses for this new feature.

Previously, point cloud data was solely used as reference points to be displayed or used in converting to 3D. Whereas, the point cloud data modeled in UC-win/Road can be used in various ways, such as to verify projects with 3D models and VR models that were created during the planning stage with high precision by measuring accurately the complete 3D objects and roads.

Fig. 1:

Fig. 1:

3D laser scanning Fig. 2:

Fig. 2:

Point cloud data imported into UC-win/Road

(Nihonbashi, downtown Tokyo)

FORUM 8 is launching "3D Laser Scanning and Modeling Service" using Nikon-Trimblefs 3D laser scanning device. Using this service, customers can receive assistance in collecting and modeling point cloud data. Since we start offering VR modeling service using point cloud data provided by clients at the same time, we are able to provide VR modeling service (UC-win/Road Support Service) using data provided by clients and data provided to clients. FROUM8 has already imported point cloud data and tested them, with the help of various scanner makers, thus, we can guarantee that we are able to display and edit of data with more than 20 million points in real time.

3D laser scanning service has following features, and the procedure begins with decision of the measurement position, the scanning and then the post-processing, as shown in the below diagram.

Point cloud data model in color can be acquired as above.

UC-win/Road Point Cloud Data Plug-in option can be used to generate TIN data from laser-scanned point cloud data and model the terrain using terrain patch function, as well as to import point cloud data.

Positions of the point cloud data can be adjusted by moving in parallel and rotating them inside the 3D space.

With the plug-in's data export function, users can export the terrain data, generated from the point cloud data, in Land XML to a third party program.

2. 3D Physical Modeling service

- We are pleased to offer customers the ability to produce a variety of 3D physical models using the outputs from UC-win/Road, UC-win/FRAME(3D), UC-1 Series and Allplan on a special 3D printer.

For this service, we use a Zprinter 650, the highest spec model from Z Corporation. Zprinter 650 can create full color 3D models using inkjet printing method. It can produce physical models with a maximum size of 254mm (w) x 381mm (h) x 203mm (d), the largest in the industry.

Larger models can also be produced by dividing up the digital model into smaller sections and then merging them to reproduce entirety of the final physical model.

The Zprinter 650 can read STL, VRML, PLY, 3DS, ZPR file formats. Other file formats can be utilized by using other 3D modeling tools, such as 3ds Max, therefore, 3D models can be generated in virtually any 3D model formats to be modeled.

Fig. 3: Zprinter (Tokyo HQ's showroom"

Fig. 3: Zprinter (Tokyo HQ's showroom"

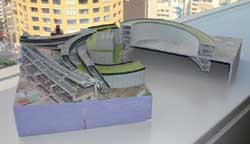

The image below shows a physical model produced by Zprinter 650, using a highway junction model data from UC-win/Road; the piers were produced based on the results from UC-win/FRAME(3D), a non-linear linear analysis program. From the physical model in the below image, the junctionfs entwined loop roads and the details of the steel tower and the ventilation facilities can be seen.

Fig. 4:@above Ohashi JCT cross section model

Fig. 4:@above Ohashi JCT cross section model

UC-win/FRAME (3D) can output the deformation data in standard 3ds format. The physical model shown was produced by the Zprinter 650 using the 3ds data. Deformed condition is reproduced as a physical model.

UC-1 and Allplan are both capable of exporting models in 3ds, therefore, 3D physical models can be produced using these software programs.

Using the 3ds Max Plug-in, gPOV-ray to Maxh, which was jointly developed with Associate Professor Kobayashi of Arizona State University, UC-win/Road data and terrain data can be exported to 3ds Max; choose the region to be reproduced and adjust the model data including the cuttings. Then users can export the data in OBJ file format which is used in many CG software programs and import the data into "Magic", a special program for creating 3D physical models. Magic will correct modeling errors, configure the data for modeling and finally produce the physical model using the Zprinter.

Time that the Zprinter 650 takes to produce models varies on the size of the model (from less than an hour up to ten or more hours), but compared with the time and effort that is taken for the production of architectural models and large-scale city models, Zprinter 650 can produce models in short time period as long as all the necessary data is available.@It is needless to say that 3D models can be used for various purposes including design examinations, detailed verifications and exhibitions.

3D Modeling Service sample quotation

3D Modeling Service sample quotation

1: Taishi Junction Model

Total Man-hour@(Sub-total A) 2.6(h) Man-hour@(Sub-total B) 28,480yen Direct labor costs(Sub-total C=A*B) 74,048yen Administration cost (Sub-total D) 37,024yen Material cost, indirect cost@(Sub-total E) 37,950yen Total(C+D+E) 149,022yen 2: Ohashi Junction model (north part)

Total Man-hour@(Sub-total A) 2.6(h) Man-hour@(Sub-total B) 28,480yen Direct labor costs(Sub-total C=A*B) 74,048yen Administration cost (Sub-total D) 37,024yen Material cost, indirect cost@(Sub-total E) 296,010yen Total(C+D+E) 407,082yen

Taishi Junction Model and Ohashi Junction models are created by

Metropolitan Expressway and were past VR contest winners

3D VR Simulation Contest review

3. 3D Drawing Service

- In addition to the existing analysis support services (UC-win/FRAME(3D) analysis support, Ground analysis support, EXODUS/SMARTFIRE analysis support, xpswmm analysis support x Buildings energu simulation ), FORUM 8 have launched "BIM 3D Drawing Option Service" and "Total Reporting and Drawing Service".

In "3D Drawing Service", we provide 3D and 2D drawings using Allplan, an integrated BIM solution. Deliverables are supplied as data files and we can provide Allplan 3D data (compatible with IFC) as final deliverables.

We have introduced here@"3D Laser Scanning and Modeling Service", "3D Physical Modeling Service" and "3D Drawing Service".

Through these 3D solutions, we provide measurement of real environment, modeling and simulation and output in 3D data.

Fig. 5: 3D Drawing Option Service (Abut)

Fig. 5: 3D Drawing Option Service (Abut) Fig. 6: 3D Drawing Service (U-type retaining wall )

Fig. 6: 3D Drawing Service (U-type retaining wall )

3D Laser Scanning and Modeling Service: started on July 1st, 2010

3D Physical Modeling Service: started on July 1st, 2010

3D Drawing Service: started on May 1st, 2010